Understand the latest developments, focus on industry trends, and interpret professional encyclopedias

Product Features:

1. Mechanical bolt, safe and reliable, easy to install;

2. The internal device shall avoid the conflict between the connection of the water transport device and the external installation parts;

3. The coating process is added on the surface of the product, and the high abrasion resistance greatly increases the service life of the secondary ejection mechanism.

Installation instructions:

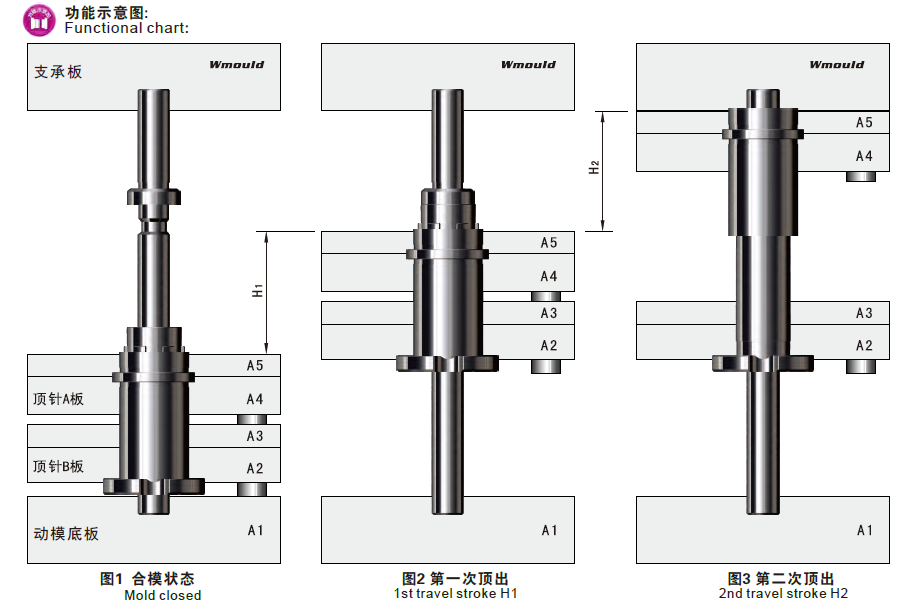

· Accurately calculate the ejector stroke, which can be cut off at both ends of the ejector rod according to demand and then used;

· Refer to the frame size drawing of installation, and note that all installation holes must be concentric and perpendicular to the parting surface;

· Remove the outer bushing and ejector rod, install the outer bushing on the ejector Plate A, and fix the main body on the ejector plate B with cup head screws;

· Reinstall the outer bushing back to the main body and insert the ejector rod to install it between the supporting plate and the bottom plate of the moving die;

· It shall be noted that accurate calculation is required before installation, and the top travel cannot be adjusted after installation;

· The movable part must be kept clean and lubricant should be used regularly to keep it smooth;

· Conduct coordination function test to check whether all parts of the secondary ejection mechanism are smooth and whether the stroke is consistent;(It is recommended to test on the closing machine or injection machine.

Crane is strictly prohibited)

· The template should be installed symmetrically in a complete set, and the stroke of several ejector mechanisms should be completely consistent. Otherwise, the force of a single reset mechanism will be caused.

The component will break due to the force imbalance;

· The operating temperature range of the second ejection is normal temperature to 120 ℃;

· This device is a precision part, so please do not cooperate with other self-processed parts. Your company will be responsible for any abnormity caused by this.

· Select 20, 26 or 32 mm diameter (small, medium, large) and thimble plate stroke range (first, second stroke) on the mold

Choose the type and specification of the second ejection.