One-stop Solution of Mould Components

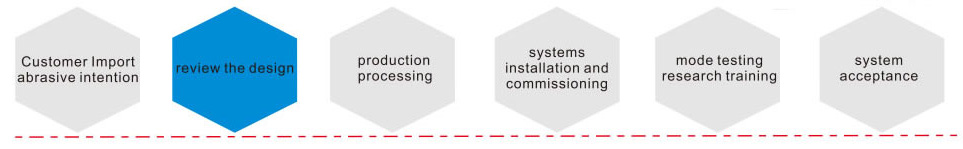

Import process automation systems:

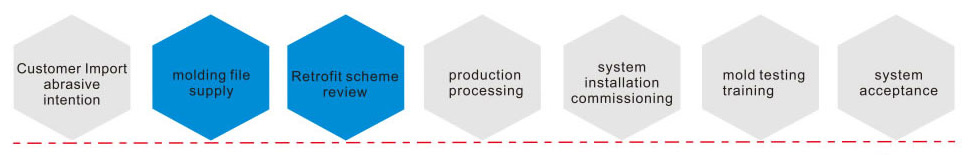

Import process automation systems:

Early introduction phase, we wiII provide complete guidance, from the design,manufactu re, assem bly, test mode, problem analysis, deal with a series of operations was free to do technology transfer entireIy to the customer.

New MouId:

Exist ing Mould:

1 , In order to ensure the smooth development and implementation of system solutions, the need to provide the following relevant information;

Complete mold 3D drawings must include the injection pin location ,cooling circuit diagram, A / B plate and mold core structure.

Complete mold 3D drawings must include the injection pin location ,cooling circuit diagram, A / B plate and mold core structure.

All plastic molded plastic material types, such as ABS \ PC \ PP \ PA + GF, etc.

All plastic molded plastic material types, such as ABS \ PC \ PP \ PA + GF, etc.

Whether the transparent parts, exterior parts or products belonging to the internal structure, etc.

Whether the transparent parts, exterior parts or products belonging to the internal structure, etc.

Before and after the fil m transport (hot oil or water at room temperature or cold water)

Before and after the fil m transport (hot oil or water at room temperature or cold water)

2, 3d drawings shall be provided to ensure that the reality of the actual state of the mold , beca use our program is designed based on customer designed for drawing, customers will bear the loss if the 3D drawing provided is different with the actual data.

3, Position for the a uto matched system will base on our specification for machining.( We will provide for machining in ppt file and on site training.) If machining does not follow specification , all the losses ca used will be bea r by your company) be underta ken.

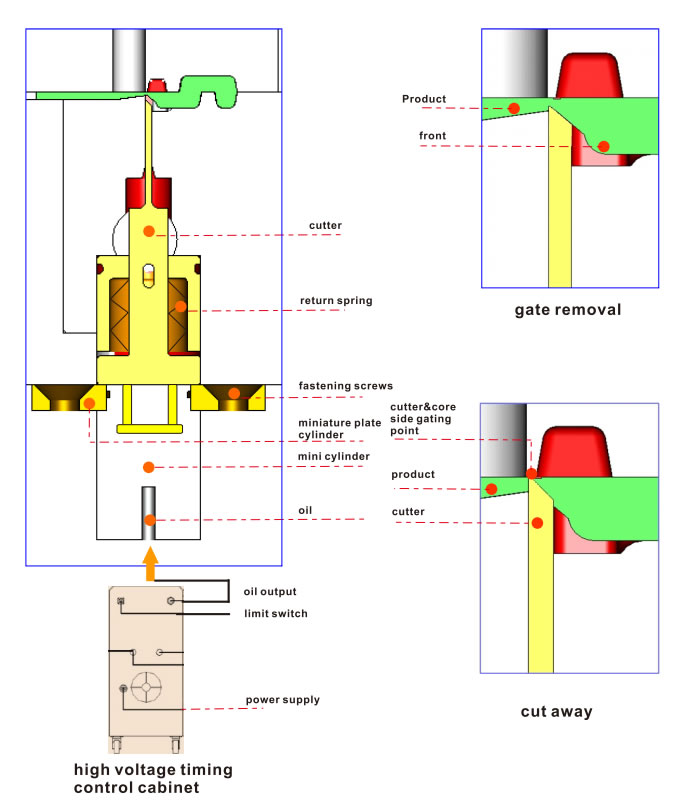

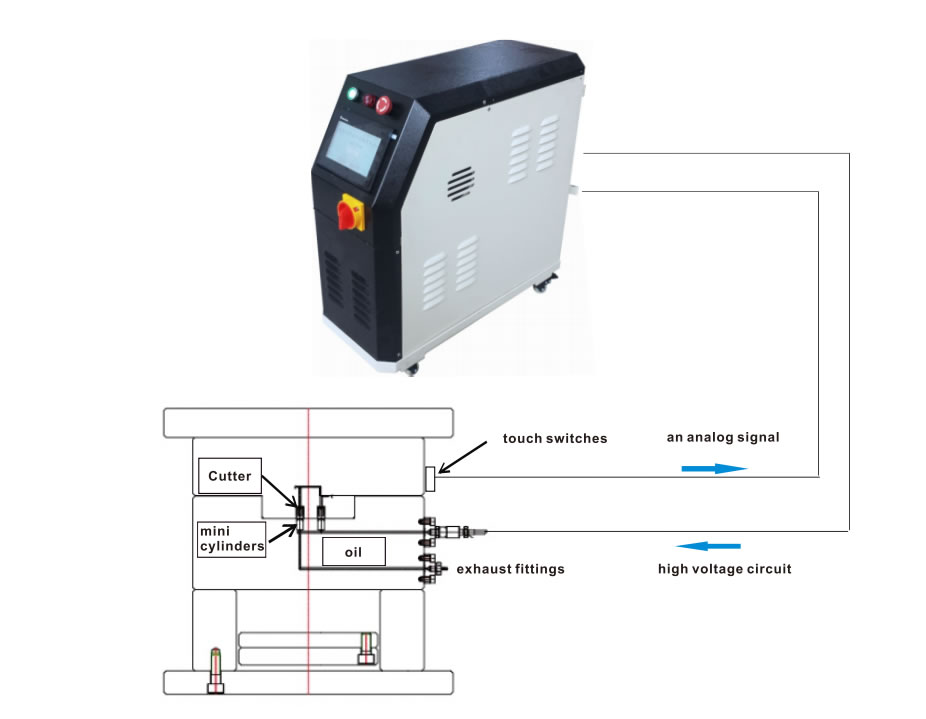

Molding automation system works:

Molding automation system works:

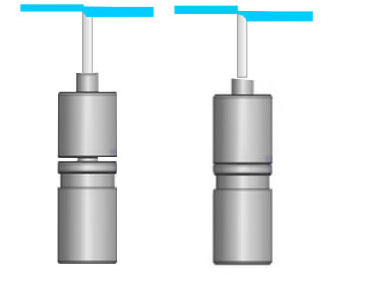

During product I nj ection ( holding process) high press ure ti min g control cabinet wiII provide ultra-high press ure to operate micro-cylinder piston.

Miniature cylinder piston push the kn ife to c ut off the to p of the head mater iaI products.

Depending on the product structure and mold, high press ure timing control cabinet time can be adj us ted, and eventua Ily reac h the best results.

High pressure timing control cabinet

High pressure timing control cabinetUsing functional modular design and manufacturing andmaintenance more convenient.

Output pressure up to 7000 ~ 1000KG /F and the output pressure is more stable, faster response time.

Touch type design, operation more convenient and intuitive.

The timing controller single / double timing controller are twotypes of options.

External Accessories

External Accessories Limit switch contact block |  micro-channelplate cylinder |  hose connectorseat |

Limit switch contact block |  adjustable through connector |  Tubing connector seat |

high hydraulic way (can withstand pressures up to 800-1200kg /cm3) |  high-pressure tubing |  process plate (knife adjustment jig) |

straight exhaust |

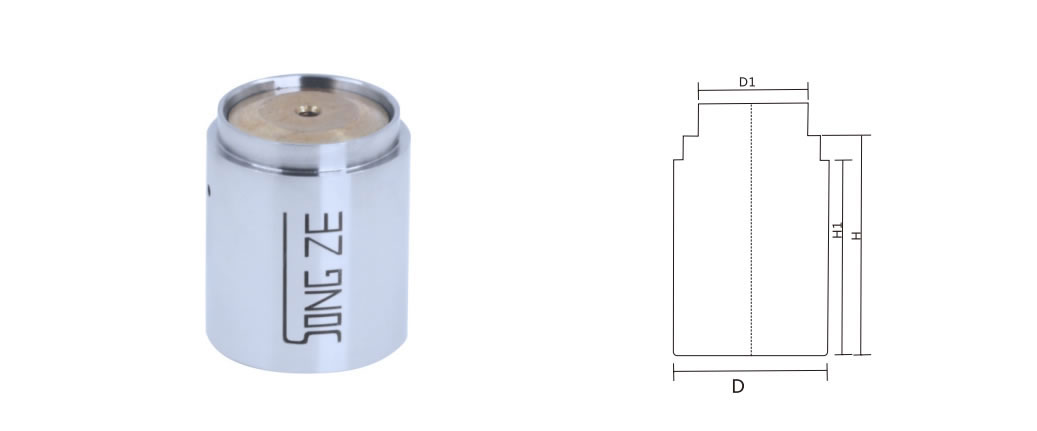

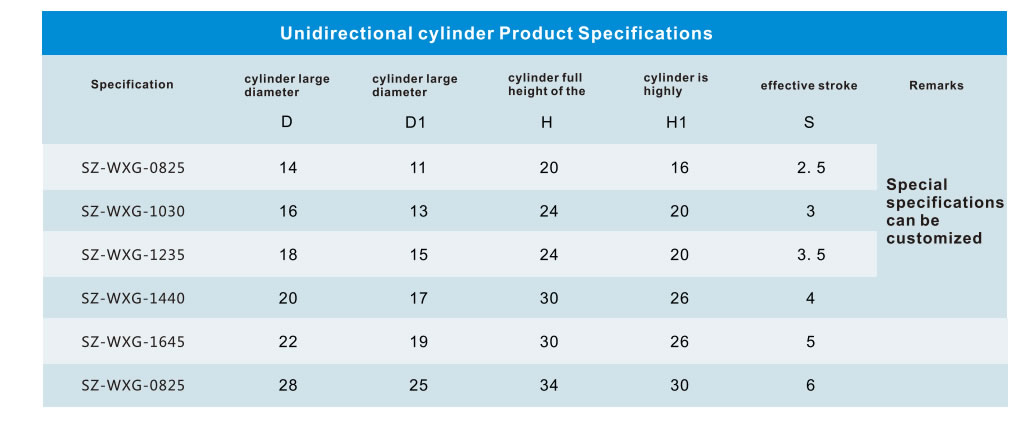

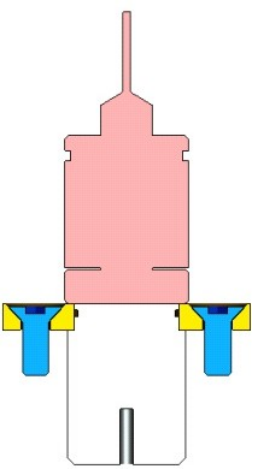

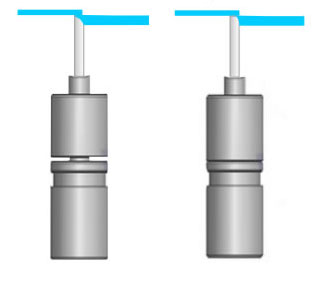

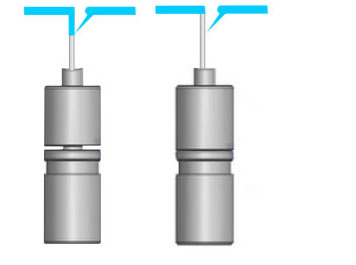

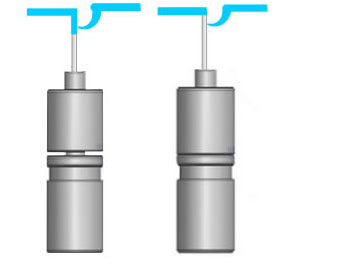

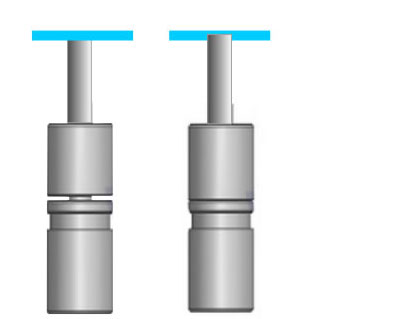

Unidirectional cylinder:

Unidirectional cylinder:

Note: One-way cylinder stroke must be within the effective stroke range, the stroke and the damage is not using thescope of the product warranty 100,000 /year

Explanation:

High-precision equipment carefully lapped to ensure the accuracy of the cylinder, cylinder lifespan(100,000 times or 1 year)

High-precision equipment carefully lapped to ensure the accuracy of the cylinder, cylinder lifespan(100,000 times or 1 year)

Special Note: Each mini-stroke cylinder control, please use within the effective range of the fuel tankusing over-travel will cause damage to the fuel tank, and the resulting damage will not be fixed withinthe scope ofrepair.

Special Note: Each mini-stroke cylinder control, please use within the effective range of the fuel tankusing over-travel will cause damage to the fuel tank, and the resulting damage will not be fixed withinthe scope ofrepair.

All the cylinders at the factory gone through 120 degrees to 180 degrees), testing before delivery to client

All the cylinders at the factory gone through 120 degrees to 180 degrees), testing before delivery to client

Since micro fuel tanks smaller, so please after processing oil should be thoroughly clean up oil in iron, in orderto avoid blockage in the work process iron cylinders, reducing the transmission of pressure, and even lead toloss of function of the fuel tank.

Since micro fuel tanks smaller, so please after processing oil should be thoroughly clean up oil in iron, in orderto avoid blockage in the work process iron cylinders, reducing the transmission of pressure, and even lead toloss of function of the fuel tank.

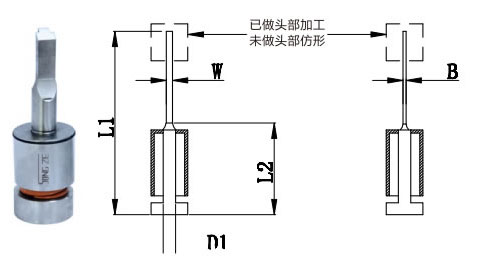

Introducing the knife

Introducing the knife cutter |  plate cylinder |  Sectional view |

mini cylinder |  flathead screws | |

standard |  secondary processing |

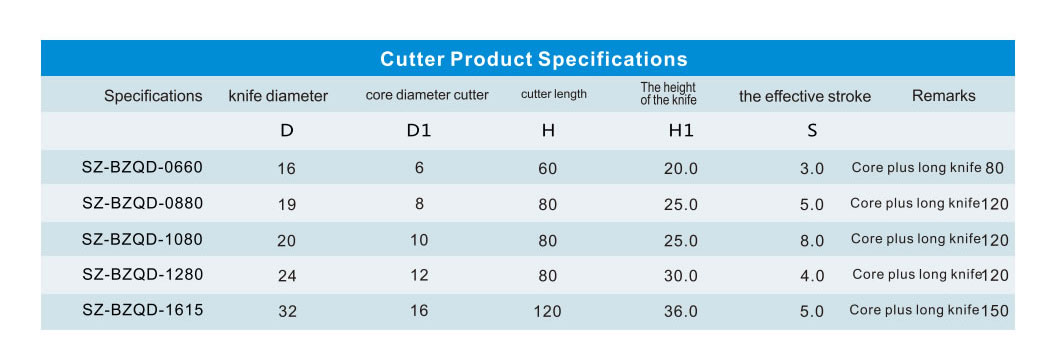

Cutter

| Cutter module features

|

Standard cutter:

Standard cutter:

|

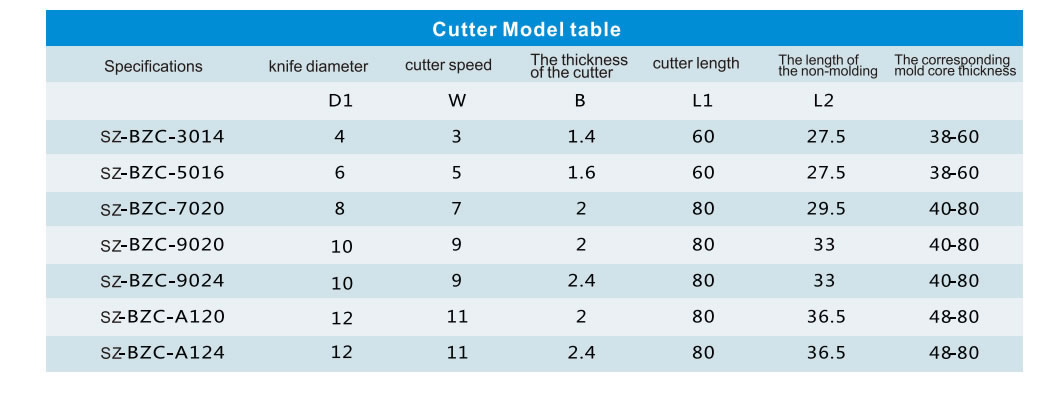

Forming cutter:

Forming cutter:

|

|

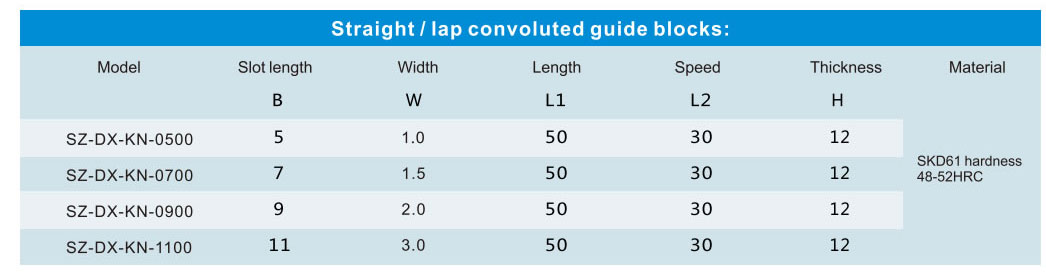

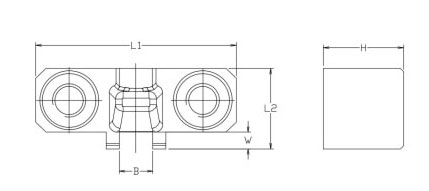

Straight/lap convoluted guide blocks:

Straight/lap convoluted guide blocks:

| Note: 1 or more for the company standard, non-standardspecifications can be customized supply. 2. The above specification application needs changetimely notification update |

Explanation:

Fitter with convenientfast molding operation.

Fitter with convenientfast molding operation. Easy to set up follow-up changes, gate changes.

Easy to set up follow-up changes, gate changes. Prevent the hole cutting position resulting inincreased wearand tear maintenance costs

Prevent the hole cutting position resulting inincreased wearand tear maintenance costs Guide block internalflow channelis fabricatedby the customer.

Guide block internalflow channelis fabricatedby the customer.

The first models ofcold-slug-free

The first models ofcold-slug-free Customers can order non-standard

Customers can order non-standard Materialis:S136/SKD61hardness:48-52HRC

Materialis:S136/SKD61hardness:48-52HRC

Shear outletApplication:

Shear outletApplication:| Gate side applications: Cutter head contour machining, precision removalof water,without leaving burrs  | Ring gate Application: Cutter made into a style similar to INFO, thewhole annular nozzle removed  |

Shaped gate applications: | Lap Gate Application: Cutter head contour machining, precisionnozzle removed, leaving no burrs  |

| Submarine Gate Application: Generally suitable for the bones plastic insertionproducts by extrusion thermal separation principleto avoid the chips, improve transparency productsgenerated noise, but if the product directly into theplastic on the way, is not suitable for use as It hasproduced marks, affecting the appearance.  | Horns Gate Application: Generally suitable for the bones plastic insertionproducts by extrusion thermal separation principleto avoid the chips, improve transparency productsgenerated noise. However, if the product directly intothe plastic on the way, is not suitable for use,it shouldhave produced marks, affecting the appearance  |

Secondary molding applications:

Secondary molding applications: Short mould&weld line appearance problem with thin thickness for the product.

Short mould&weld line appearance problem with thin thickness for the product.

Through the implantation of the automation system, when dispensing, characterized in parts of the cutter inserts to no action, until dispensing is completed, the cutter assembly line operation, reduce gum or moldingcharacteristics, to achieve the purpose.

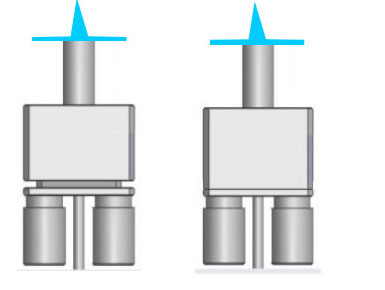

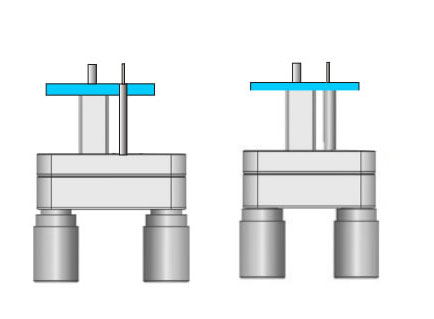

Simplify the mold structure application

Simplify the mold structure application

By forming the sub-assembly + miniature cylinder substitute Pulling assembly line position, can effectively reduce the mold block.

| In the secondary molding mold Resolve thin plastic mold located unsaturated bond lineobvious problems  | Application of internal modelsecondary pierce |